Industrial Screen Rotor Manufacturers in India, Suppliers in India

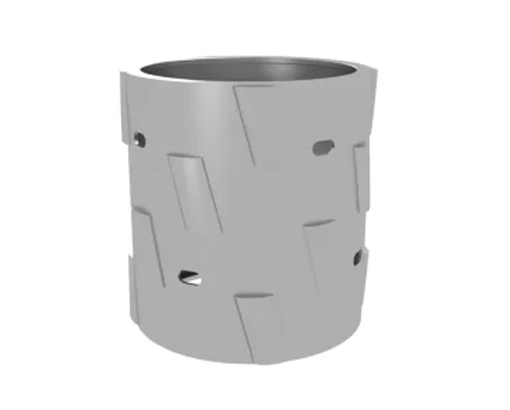

Intercontinental Exim Corporation is leading Industrial Screen Rotor manufacturers in India and suppliers in India. With experience of several years and a pro-active attitude, we deal in supplying highly effective and tough rotor sets for industrial screening applications. We develop our rotors to perform well under aggressive operating conditions without sacrificing energy-saving and maintenance-free performance.

Types of Industrial Screen Rotors We Produce:

As well-known Industrial Screen Rotor manufacturers in India, we are providing the best quality of a wide range of screen rotors such as:

- Pressure Screen Rotor: We make and supply Pressure Screen Rotors exclusively for pulp and paper mills, where minimum energy consumption and maximum fiber separation are extremely critical. Our rotors have the ability to deliver maximum pulsation to reach higher screening efficiency and screen basket wear to the minimum. We now offer advanced designs featuring variable vane profiles and geometry made bespoke for flow simulation to deliver better performance with the changing pulp consistencies.

- Pressure Screen Rotor: We make and supply Pressure Screen Rotors exclusively for pulp and paper mills, where minimum energy consumption and maximum fiber separation are extremely critical. Our rotors have the ability to deliver maximum pulsation to reach higher screening efficiency and screen basket wear to the minimum. We now offer advanced designs featuring variable vane profiles and geometry made bespoke for flow simulation to deliver better performance with the changing pulp consistencies.

- Low Consistency (LC) Screen Rotor: Our Low Consistency Screen Rotors are particularly well-suited for screening in LC pulp processes where smooth running and low power consumption are essential. The rotors create controlled turbulence and plugging is minimized to the lowest level possible, with high capacity. We use some low-vibration design principles and optimized slot interaction angles in order to make screening more stable.

- High Consistency (HC) Screen Rotor: We supply High Consistency Screen Rotors that are used in thick stock screening machines in which the fiber consistency ranges from 3% to 5%. Our rotors are precisely engineered for offering high agitation without damaging the fiber structure. The rotors provide uniform pressure pulsation and counter screen blinding and clogging under heavy loads smoothly.

- Fine Screen Rotor / Reject Screen Rotor: We also specialize in Fine Screen Rotors and Reject Screen Rotors to work in last stages of screening for recognizing fine fibers from rejects. Our designs emphasize precise pulsation for facilitating maximum fiber recovery with removal of impurities. These rotors are made up of thin-profile vanes and narrow gaps to have precise control over separation efficiency.

Key Features of Our Industrial Screen Rotors:

As dominant industrial screen rotor suppliers in India, our all types of new industrial screen rotors are filled with new features inside such as:

- Smart Design Geometry: We employ CFD (Computational Fluid Dynamics) technology to design precision each vane and blade profile. This enables us to optimize flow patterns, minimize turbulence, and provide smooth circulation of pulp during the screening cycle. Our rotors thus ensure excellent hydraulic performance with low energy loss and less fiber damage.

- Strong Materials: We produce our rotors from the highest quality wear-resistant stainless steel, duplex alloys, and hardened surface materials. These are chosen primarily for their toughness within hostile and abrasive conditions like those seen in pulp and slurry systems. This provides a longer life cycle with robust premium performance under sustained service.

- High Wear Tolerance: We integrate supported construction and progressive metallurgy with our rotors to render them wear and tear-proof. They are cavitation, corrosion, and extreme mechanical stress-resistant designs and thus perfect for high-performance industrial applications. Our rotors are capable of sustaining their performance integrity over a long period of time, thereby keep untimely breakdowns and expensive downtimes at bay.

Benefits of Selecting Intercontinental Exim Corporation

These all types of industrial screen rotors give certain types of benefits such as:

- Reliability of Operation: We guarantee each rotor that we manufacture with consistent performance over a broad set of operating conditions. We also test and verify our designs to operate under high-load and high-consistency use. Your plant can anticipate improved uptime and more reliable screening operations with our rotors.

- Lower Energy Costs: We assist in minimizing your energy expense with low-power rotors with no sacrifices in overall delivery. Our carefully designed solutions minimize coupled motor loading and provide peak hydraulic efficiency. This translates to considerable cost savings and enhanced overall process economics in the long run.

- Enhanced Equipment Life: We employ better materials and balanced construction to make sure that our rotors are long-lasting. Their erosion, corrosion, and impact resistance increases their lifespan greatly, lowering the rate of replacement. This prolongs them, resulting in cost benefits over the long term and making sure that your operation is efficient and consistent.

- Process Optimization: We collaborate closely with your engineering staff to develop rotor solutions that are tailored for your screening process. Our vane angle, size, and flow pattern are optimized to suit your operation, maximizing fiber recovery and minimizing waste. This maximizes productivity, product purity, and environmental sustainability in operations.

Applications of our Industrial Screen Rotors:

Being the best industrial screen rotor suppliers in India, our all types of Industrial Screen Rotors are included with new feature and highly used in multiple applications such as:

- Pulp & Paper Industry: We provide total service to the paper and pulp market with rotors for first, coarse, fine, and reject screening in mechanical, kraft, and recycled fiber systems. Our rotors provide even pressure pulsations and less plug gages on the screen, permitting greater screening capacity. Computerized compatibility and improved wear protection allow them to help the paper mills to attain the highest fiber recovery at the lowest operating cost.

- Textile Fiber Processing: We provide rotor technology solutions to the textile sector where viscose, rayon, and synthetic fiber pulps need to be agitated evenly but gently. Our low-vibration rotors ensure enhanced fiber quality and improved filtration performance. They are built corrosion-resistant to provide long life and lower maintenance despite chemically active operating conditions.

- Water Treatment Plants: We provide rotors that can efficiently separate fiber materials and suspended solids in effluent plants and wastewater treatment plants. Our systems optimize zero-discharge processes through improved sludge separation and recovery of fibers. Through greater smart monitoring, the rotors save water and meet regulations.

- Biomass and Agro-Waste Processing: We have specialty rotors available for pulping agricultural residues such as wheat straw, bagasse, and bamboo with broad applications in green papermaking. These rotors can pulp fibrous and twisted fibers with maximum energy efficiency. Due to its strength to support unstable process conditions, it is best suitable for rural and biomass mills.

Intercontinental Exim Corporation is a leading industrial screen rotor manufacturers in India, suppliers in India. We combine precision engineering, innovation and industry expertise to provide high-performance Industrial Screen Rotors that set new standards for reliability and efficiency. Whatever energy efficiency, product quality or process stability is concerned, rotor solutions from us will live up to your high-end expectations. Supported by in-house R&D and globally renowned support services, we continue to be your partner of choice in process screening technology. Let's create the future of screening today.