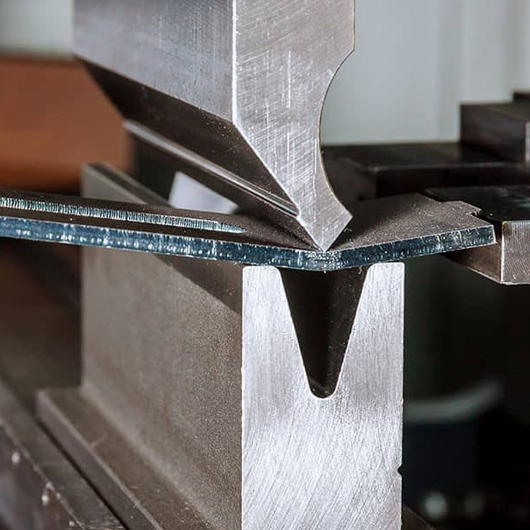

Press Break Forming

Press Break Forming is a precision metal forming process that involves applying controlled pressure to bend or break a metal sheet along a predetermined line or contour. This method is typically used to create sharp, clean breaks or bends in the material, often forming intricate shapes and components with high accuracy. The process utilizes specialized press equipment, which applies force in a localized area, allowing for the precise control of the break point while minimizing material deformation and waste. As a result, press break forming is highly valued in industries such as automotive, aerospace, and construction, where maintaining material integrity and achieving tight tolerances are critical. Advanced press break forming systems incorporate computer numerical control (CNC) technology and real-time monitoring to ensure consistency and repeatability, which in turn reduces production downtime and improves overall quality. Moreover, the process is both cost-effective and efficient, enabling manufacturers to produce complex designs with reduced lead times and lower labor costs, making it an indispensable technique in modern metal fabrication and mass production.