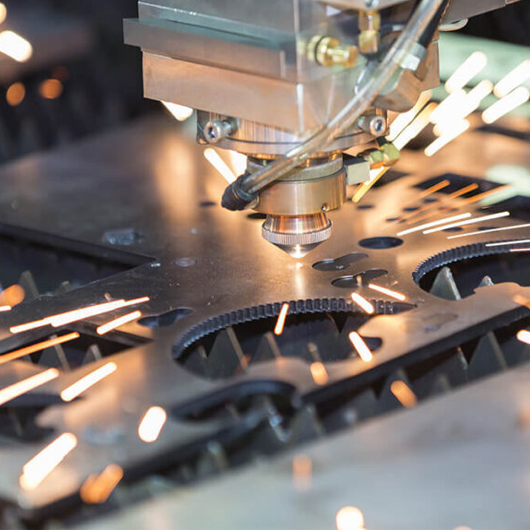

Laser Cutting

Laser Cutting is a highly precise and efficient manufacturing process that utilizes a focused laser beam to cut, engrave, or etch materials with exceptional accuracy. This advanced technology is widely used in industries such as automotive, aerospace, electronics, and metal fabrication due to its ability to produce intricate designs, smooth edges, and minimal material waste. Laser cutting works by directing a high-powered laser through optics and computer numerical control (CNC) to achieve precise cuts on various materials, including metals, plastics, wood, and composites. One of the key advantages of laser cutting is its ability to handle complex geometries and thin to thick materials without the need for extensive tooling. The process is contactless, which reduces mechanical stress on the material, ensuring high-quality, burr-free finishes. Additionally, laser cutting supports rapid prototyping and mass production with high repeatability, making it an ideal solution for both custom and large-scale manufacturing. With advancements in fiber and CO₂ laser technology, modern laser cutting systems offer improved speed, efficiency, and energy savings, reinforcing their critical role in precision engineering and industrial fabrication.